PET-based Solutions

The potentials of PET-based foam cores for enhanced structural integrity

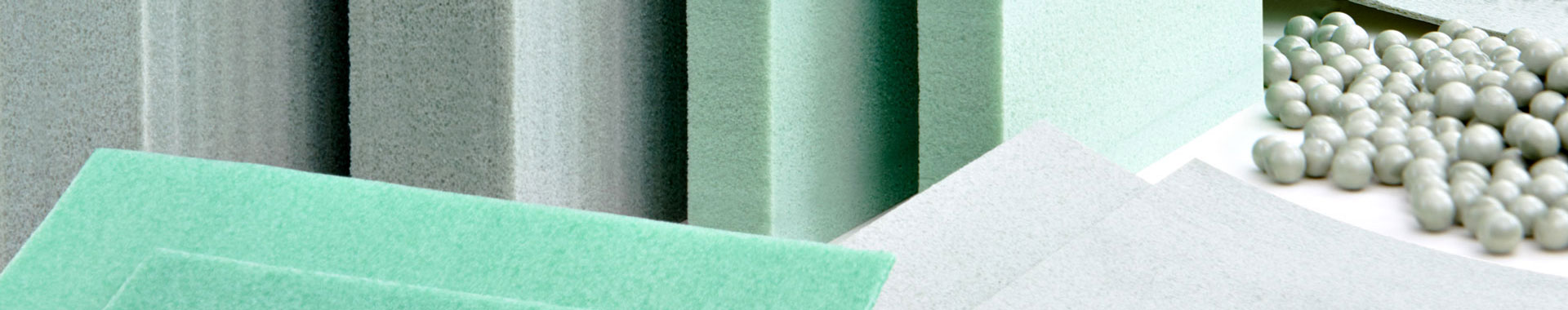

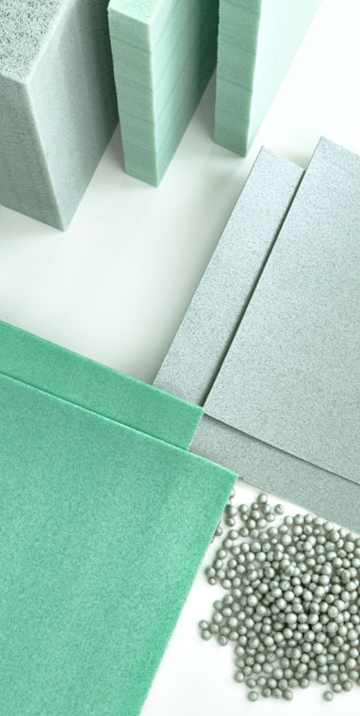

Transforming PET into high-quality system solutions

Since 2005, we have been leading the way in the development of polyethene terephthalate (PET-based) foam cores for the composite industry. Our commitment to innovation and sustainability has driven significant investments in research and development, resulting in our process technology for PET foam production. In 2010, we achieved a milestone, introducing the world's first structural foam core crafted from 100 percent recycled PET (rPET) plastic. Today, our entire PET foam product portfolio is based on this pioneering process, allowing us to transform post-consumer PET beverage bottles into high-quality resources that are fed back into the production cycle.

Did you know that our ArmaPET solutions are made of recycled PET bottles, reducing waste and demonstrating a significantly lower carbon footprint than competitive materials?

A sustainable, versatile and highly durable substitute

PET-based insulation outperforms conventional materials in key parameters such as thermal performance and structural integrity, offering more sustainable and durable body structures.

Superior thermal insulation

Superior thermal insulation

ArmaPET offers outstanding thermal insulation properties, ensuring optimal temperature control in a wide range of applications, from transport to building construction.

Unmatched structural strength

Unmatched structural strength

ArmaPET's structural foam cores provide exceptional strength-to-weight ratios, making them ideal for demanding applications such as high-speed train body structures and wind turbine blades.

Sustainability at its core

Sustentabilidade em sua essência

O uso de garrafas PET recicladas pela ArmaPET não só reduz o impacto ambiental, como também reforça as credenciais sustentáveis do material, alinhando-se à crescente demanda por soluções ecologicamente responsáveis.

Versatility through thermoforming

Versatilidade graças a termoformagem

A natureza termoplástica do ArmaPET abre portas para processos de termoformagem e termomoldagem, expandindo sua aplicabilidade para uma gama ainda maior de usos. Seja no setor de energia eólica, na construção civil ou na fabricação de compósitos, a versatilidade do ArmaPET se torna um recurso valioso em aplicações estruturais.